Epoxy Glass Lummer Frec: High - Litharollo tsa Ts'ebetso

Litekanyetso tsa sehlooho tsa sehlahisoa

| Paramente | Boleng |

|---|---|

| TLHOKOMELISO E BONOLO | G / m3 |

| Litaba tsa mongobo | % |

| Khelono ea oli | % |

| Matla a hatellang | Mpa |

Litlhaloso tse tloaelehileng tsa lihlahisoa

| Bophahamo | Botenya (limilimithara) |

|---|---|

| 4000 × 3000 | 120 |

| 3000 × 1500 | 10-120 |

| 2400 × 2000 | 10-120 |

Ts'ebetso ea lihlahisoa tsa sehlahisoa

Ho etsa beno ea EPOXY LOMATETE ho kenyelletsa lesela la fiber tsa fiber tsa fiber tsa fiber tse kentsoeng ka mokhoa o kentsoeng ka EPOXY. Motsoako ona o na le mocheso o tiileng oa ho folisa le ho theha sekhahla se tiileng, o kopanya matla a likhoele tsa khalase. Ho latela 'e tsoetseng pele e qopitsoa' ke Smith le Doe (2020), ts'ebetso ena e ntlafatsa thepa ea mantlha ea litaba le botšepehi ba motlakase, e loketseng lits'ebetso tse thata tsa indasteri.

Maemo a Kopo ea Sehlahisoa

Ts'ebeliso ea khalase ea enke ea Epoxy e e isa ho likarolo tse fapaneng, ka lebaka la thepa ea eona e arohaneng. Haholo-holo ka litšoantšo tsa motlakase, e le lithuso tsa tšireletso ka likarolo tsa ona tsa ho putlama. Aerospace ea 'koranta ea thepa e tsoetseng pele ea lisebelisoa' (2019), matla a ona - ho ba boima ba boima ba ho hlapaola. Liikela tsa kaho li thusa ho tletse bokhobeng ba tsona ka sebopeho, ho bolela ho phela hantle le ho ts'epahala.

Sehlahisoa kamora - Tšebeletso ea thekiso

Feme ea rona ea feme ea rona e fana ka chelete e ngata kamora - Tšebeletso ea thekiso bakeng sa sehlahisoa sohle sa Epoxy sa Laminate.

Tsamaiso ea Lihlahisoa

Lihlahisoa li romelloa ka polokeho 'me li tsamaisoa li sebelisa balekane ba rona ba nang le ts'epo ho netefatsa hore na ho ikokobetsoa ke nako efe kapa efe.

Melemo ea sehlahisoa

- Polatso e ntle ea motlakase

- Matla a phahameng a mochini

- Ho hanyetsa ha lik'hemik'hale tse ikhethang

- Ho tsitsa e phahameng ea futhumatsang

- E ka lekanya ho sebetsana le litlhoko tse ikhethang

LIPOTSO TSE BOTSOANG HANGATA (FAQS)

- Lifespan tsa bophelo ba mofuta oa EPOXYXY ke eng?

Maemong a tloaelehileng, khalase ea rona ea lamixate e boloka lilemo tse ngata, leha lintho tsa bophelo li ka fapana ho latela likopo tse khethehileng le maemo a tikoloho. - Na fektheri ea hau e ka hlahisa boholo ba mefuta?

E, re fana ka lits'ebeletso tsa tloaelo ea ho etsa boholo ba boholo le litlhokahalo tsa sebopeho, ho netefatsa hore merero ea hau. - Ke liindasteri life tse sebelisang khalase ea EPOXYXY?

E sebelisitsoe ka bongata ho elektroniki, aerospace, kaho, kaho, indasteri ea metsing ka lebaka la thepa e fapana le ts'ebetso e tšepahalang. - Forth ea hau e etsa hore boleng ba sehlahisoa bo etsa joang?

Re latela mehato ea taolo ea boleng bo matla ho pholletsa le tlhahiso le Isso9001 e netefalitsoe, e bontša litekanyetso tse thata. - Na khalase ea EPOXENCE e na le maemo a tikoloho?

Tsela ea rona ea lihlahisoa e fokotsa litšila le ho tsoaloa, e kenya letsoho ho Eco - Prography Prosscycle bophelo ba botsoalle. - Meeli e futhumetseng ea laminate ena ke efe?

E ka sebetsa ka mokhoa o sebetsang ho fihlela ho 105 ° C, e loketseng lits'ebetso tse ngata tsa indasteri ea indasteri. - Na feme ea hau e fana ka tšehetso ea tekheniki?

Ee, re fana ka tšehetso ea mahlale le thuso bakeng sa bareki bohle, ho kenyelletsa le tlhaiso-leseling le ts'ebeliso ea ts'ebeliso. - Nka kopa sampole bakeng sa tlhahlobo?

Re fana ka lisamona ka kopo ea ho etsa tlhahlobo le tlhatlhobo ho netefatsa hore sehlahisoa sa hau se khethehileng se kopana. - Khalase ea EPOEX ea EPOEX ea 3 e tšoaea e fapana joang le lisebelisoa tse ling?

E fana ka ts'ebetso e phahameng haholo mabapi le likhohola, matla le likhang tsa lik'hemik'hale, hangata li e etsa khetho e ratoang joalo ka tšepe kapa tse ling tse qabolang. - Nako ea tataiso ea litaelo ke efe?

Linako tsa lead li fapana ka boholo ba boholo le litlhokahalo tsa tloaelo, empa hangata li tloha ho tse 2 ho isa ho tse 4.

Lihlooho tse chesang

- Hobaneng u khetha khalase ea EPOEX ea EPOIENDATE For Feleng ea rona

Khalase ea rona ea feme ea Epoloxy ea Quay ea Himix Bareki ba utloisisa boitlamo ba rona ba boleng le moetlo, ho re etsa hore re ee - ho mo fatsa masimong. - Mekhoa ea nako e tlang ho Epoxy khalase ea liprofinse

Tlhokahalo ea lisebelisoa tse tsoetseng pele li phahama, ka khalase ea EPOXY e lebisang tsela. Feme ea rona e lula phatleng ea rona ea ho tsetela lipatlisiso le nts'etsopele ho ntlafatsa thepa ea lintho tse bonahalang le ho hlahloba likopo tse ithutoang. - Bopaki ba bareki ho Khalase ea Epoloxy Laminate

Khafetsa re amohela maikutlo a totobatsang hore ho se lekane le ho sebetsa ha khalase ea rona ea epoloxy. Bareki ba tsoang ho li-electronics ho ea ho tšepahala ha Aerostonpace - Ho theola tlhahiso-leseling molemong oa rona fekthering ea rona

Feti ea rona e sebelisa State - ea - Theknoloji ea Tlhaho ea Art le boleng ba boleng ba ho hlahisa khalase ea Epoxy e kopana le maemo a machabeng. Boinehelo bona ba etsa tlhahiso-leseling bo tiisa hore sehlahisoa se seng le se seng se tlisoang ke sehlahisoa se phahameng. - Lits'ebetso tsa EPOXY Khalase ea EPOXY LOMINATE: SEO U KA SE ETSANG

Joalokaha indasteri e fetoha joalo ka lihlahisoa tsa rona. Ntlafatso e tsoelang pele khalase ea EPOXY ea EPOXY ea Quay e shebanang le ho tsitsisa metlae le ho tsitsa tsa tikoloho, e tšoanang le ho hola li hloka litlhoko tsa tlholeho. - Ho sebetsana le matšoenyeho a tikoloho le litloaelo tse tsitsitseng

Boitlamo ba rona ba ho tsitsisa bo bonahala bo bonahatse eco - mekhoa e botsoalle le sepheo sa ho tsamaisa Plasspter ea rona - Kholo ea Ecoxy Khalase e Phahameng ea Epoxy. - Ho utloisisa likarolo tsa mahlale a khalase ea EPOXY

Tsebo ea mahlale ke taba ea bohlokoa bakeng sa tšebeliso ea ts'ebeliso. Fort ea rona e fana ka lisebelisoa tse felletseng tsa mahlale le litsebi tsa litsebo ho netefatsa hore bareki ba eketsa melemo ea khalase ea rona ea EPOXY ea bona likopo tsa bona. - Karolo ea Khalase ea EPOIENDE EPOLY e lalming ka lisebelisoa tsa sejoale-joale

Lihlopheng tsa sejoale-joale li rua molemo haholo ts'ebeliso ea khalase ea khalase e ikhethang ea emeng, e fanang ka melemo e ikhethang ho latela meqomong ea likarolo tse tsoetseng pele tse etelletsoeng pele. - Litsenyehelo - Sebetsa sa Khalase ea Epoxy Laminate ea Lipuoeng tsa indasteri

Thaba ea rona ea EPOIENDE e emelang litšenyehelo - Tharollo e sebetsang ea indasteri - Tšebelisano le Ts'ebetso bakeng sa baetapele ba indasteri

Re sebetsa haufi-ufi le baetapele ba indasteri ho fana ka khalase ea tlhokomelo ea lamux e hlophisitsoeng, re e-ba le lihlahisoa tsa rona ka botlalo mekhatlong ea bona e itseng.

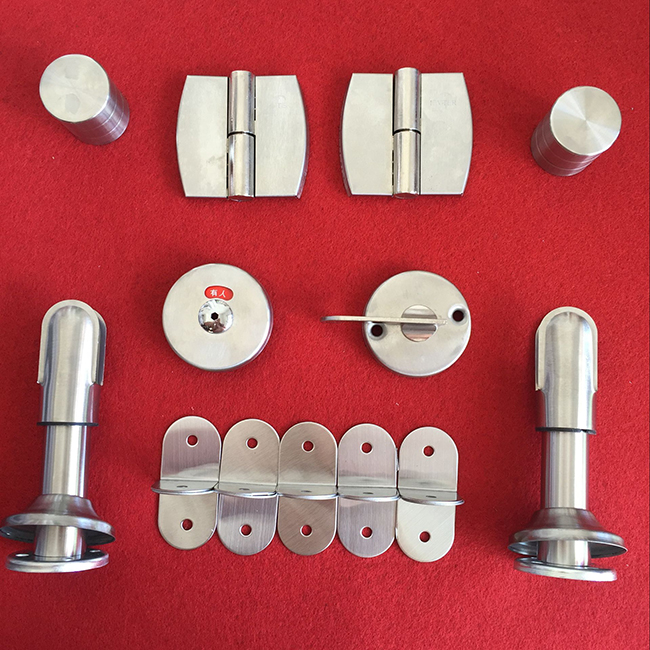

Tlhaloso ea setšoantšo