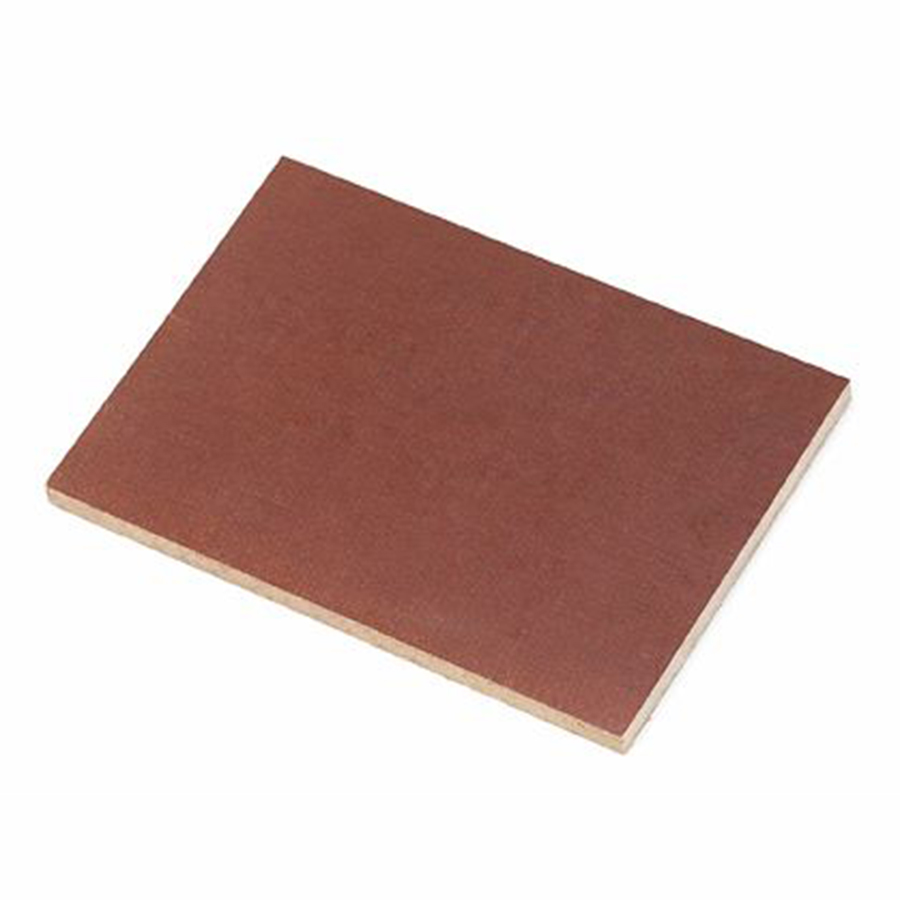

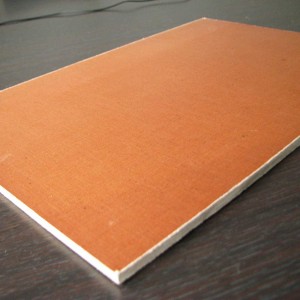

Phenolic Laminate Insulation Phenolic Cotton Lesela Board

Likopo tse ka har'a likhabinete tsa kabo ea matla: li-partitions, li-linings, li-terminal blocks, li-insulation tsa phase-to-phase, li-partitions tse tlase, litšehetso tsa ho ikopanya.

Lisebelisoa ho li-motors: likarolo tsa lihlomo tsa enjene, likoahelo tse tsamaisoang, li-slot wedges, li-pads tse tsitsitseng, li-gaskets tse tšesaane, li-brashi tsa khabone, joalo-joalo.

Lisebelisoa ho li-circuit breakers: li-shutter tsa polokeho, li-shutter tsa polokeho, li-spacers, litšitiso tsa mekhahlelo, joalo-joalo.

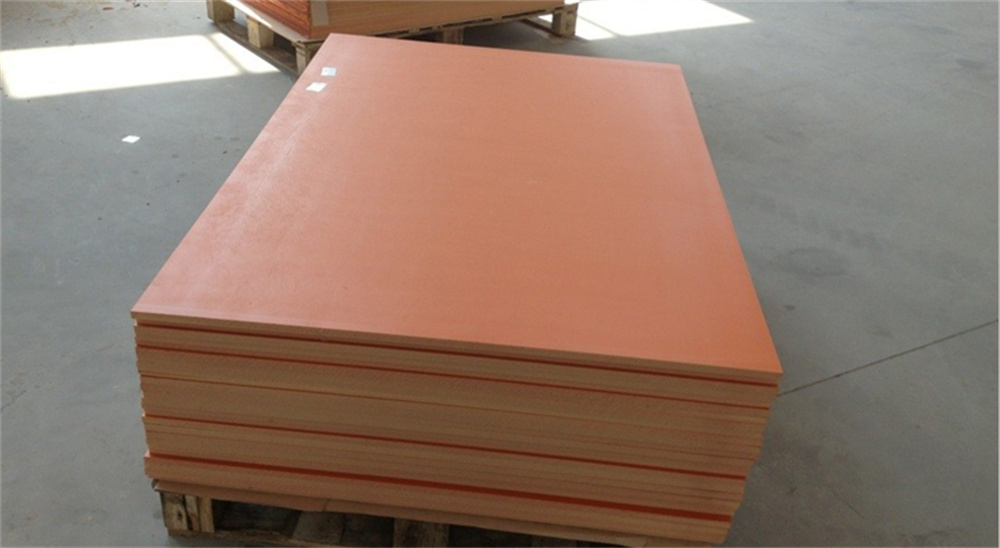

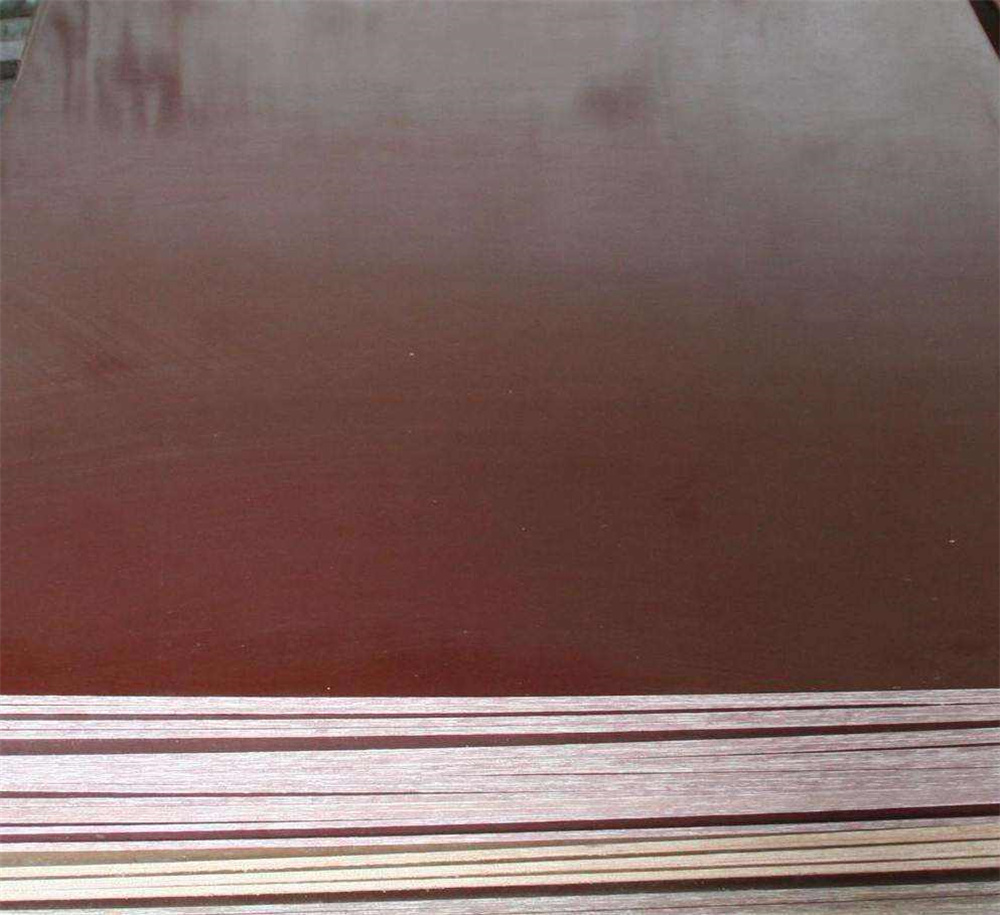

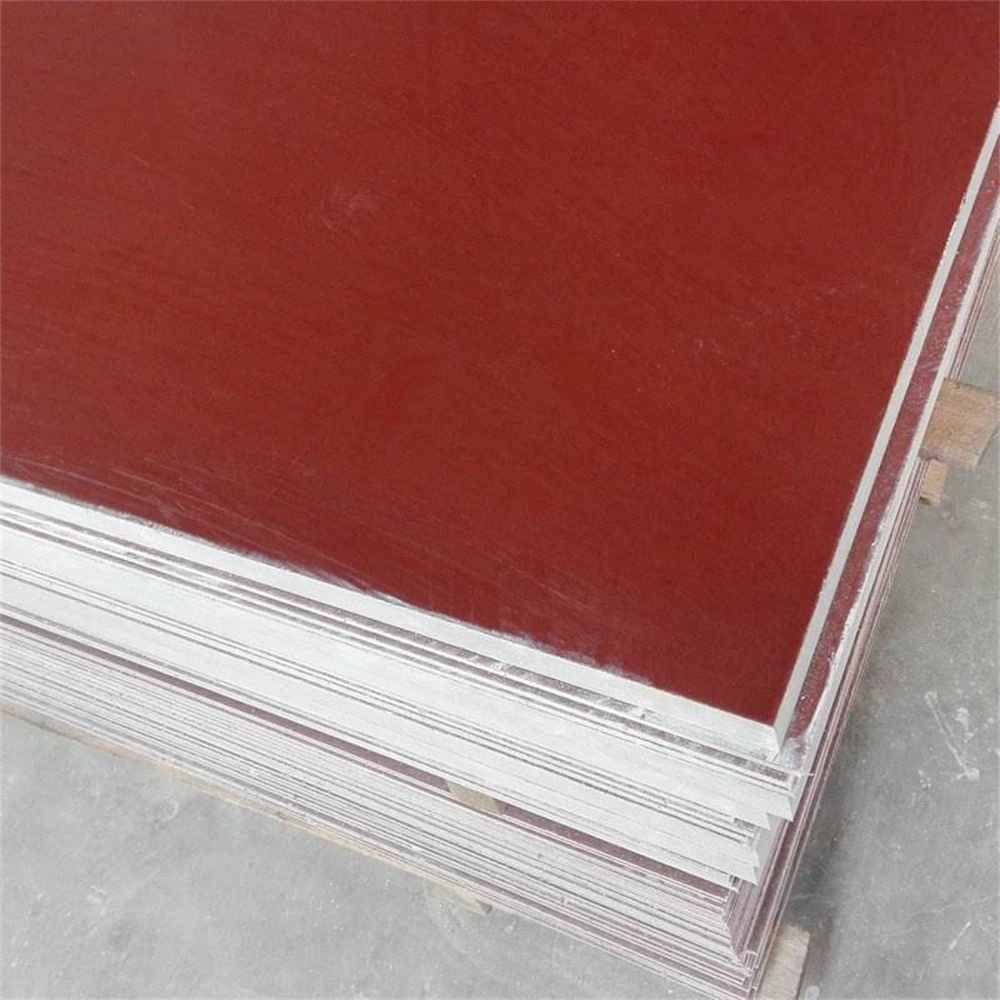

Botenya ba 0.5-120mm

Boholo ba 1030 * 2050mm

| NO. | LETLOTLO | THUTO | BOHLOKOA MAEMO |

| 1 | Flexural matla perpendicular ho laminations | MPa | ≥100 |

| 2 | Matla a amang a tsamaisanang le laminations(Charpy) | kJ/m2 | ≥8.8 |

| 3 | Matla a dielectric perpendicular to lamination(ka oli 90±2℃) 1mm ka botenya | MV/m | ≥0.82 |

| 4 | Matla a ho senya parallel holamination (ka oli 90±2℃) | kV | ≥1 |

| 5 | Insulation resistance e kentsoeng ka metsing, D-24/23 | Ω | ≥1×106 |

| 6 | Botenya | g/cm3 | 1.30-1.40 |

| 7 | Ho monya metsiD-24/23,1mm ka botenya | mg | ≤206 |